ABOUT THE FASTENERS DIVISION AT ADAMJEE ENGINEERING

Adamjee Engineering Pvt Ltd, has been engaged in the manufacturing and marketing of cold forged fasteners since 1963. With the objective of substituting the imports of screws with domestically produced products, the company launched itself into this business by initially manufacturing woodscrews for the local market. Since then, responding to the demand from the retail sector & the OEM's, Adamjee Engineering (Pvt) Limited today produces a variety of fasteners made from steel, brass, stainless steel and aluminum wire. By virtue of our wide range of products & sizes, consistent quality, timely delivery, research & development, strong customer service and depth of client base, Adamjee Engineering (Pvt) Limited has successfully maintained its position as the leading manufacturer of fasteners in Pakistan for the past 50 years.

A large part of this success can be attributed to the 360-degree philosophy that the management has inculcated throughout their workforce. This philosophy looks at all aspects of the value chain, from manufacturing and quality control to human resource development as a tool to achieve total customer satisfaction. It is this outlook and approach that has helped the company to surpass all old boundaries, reach new heights and attain its corporate vision of "sustainable growth through excellence".

Looking to the future, it is the objective of this division of the company to increase and improve its capabilities to produce "value added" fasteners for demanding applications such as the passenger car industry, commercial vehicles and eventually the aerospace industry.

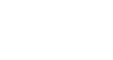

PROCESS FLOW OF MANUFACTURING OF FASTENERS

SCREWS & BOLTS

Additional machining operations are conducted either after heading or after thread rolling depending on the type of product. Quality control and inspection is carried out at each and every step.

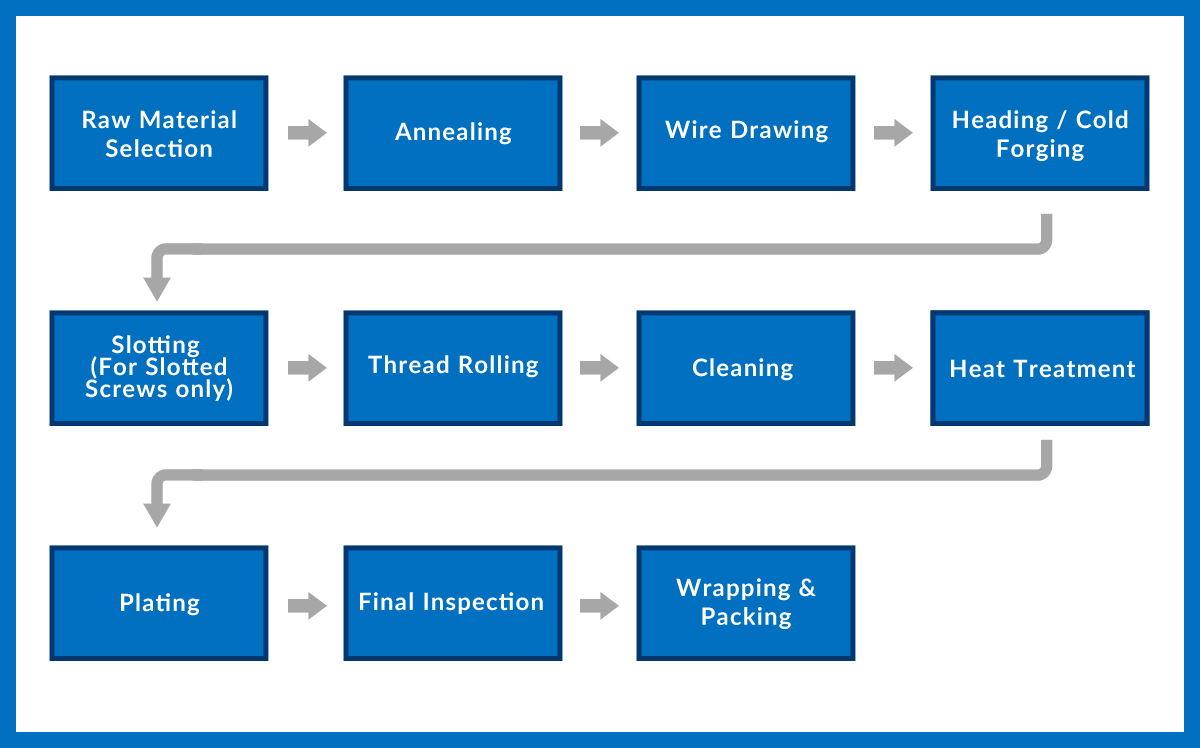

ALUMINIUM BLIND RIVETS

RAW MATERIAL SELECTION FOR FASTENERS

As is the case in most manufacturing industries, when it comes to the production of fasteners, the quality of the raw material plays a major role in the quality of the final product. Having learnt from practical experience of more than 50 years, Adamjee Engineering has made it a policy to use only the highest quality of steel wire rods conforming to AISI, SAE & JIS for its screws, rivets & bolts.

Another policy that we have adopted is that we buy our steel raw material requirements directly from manufacturers of these products. By doing so, we are able to obtain crucial information from the manufacturers on any particular consignment such as (1) Mill Test Certificates, (2) Heat/batch numbers of each coil (for traceability purposes) and (3) Reliable lead times.

PRODUCTION FACILITIES OF THE FASTENERS DIVISION

At Adamjee Engineering, we believe that the "QUALITY" of our products is the best ambassador of our company. Furthermore, we are of the opinion that most effective way to grow - in the long run - is not only to maintain the quality of what we manufacture but to continuously strive to enhance the range of our products and their applications. With this objective in mind, we have over the years established strong ties with manufacturers of machinery & equipment, raw materials, dies/tooling and accessories such as nuts & washers. With the objective of further cementing our relationships and acquiring in depth knowledge of the latest technology, we make it a point to have our senior managers and engineers visit our suppliers in the Far East on a regular basis.

Our monthly production capacity of screws/bolts is around 145M pieces whereas for the Aluminium Blind Rivets section, it is approximately 19M pieces. The heat treatment section consists of state-of- the-art gas based continuous furnaces using Endo-Gas to create a controlled atmosphere with a monthly capacity of 360 M. Tons. They are used for both case hardening/carburizing of self-tapping, drywall and self-drilling screws and through hardening of high tensile machine screws, hex bolts and socket head cap screws. Our Fasteners and Blind Rivet manufacturing/machining facilities consists of machines capable of manufacturing a vast majority of the types of fasteners available in the marketplace these days.

Apart from our core strength of being able to offer cold forged, machined/turned screws, bolts and studs, we take pride in the wide range of surface treatments that we are able to offer such as nickel plating, zinc plating, yellow zinc plating, brass plating, chrome plating and phosphating. In addition to the aforesaid, we have also introduced Antique, Champagne, Black & Olive coloured fasteners over the past few years.

PRODUCTION CAPABILITIES

- Gauge/Size of Fasteners - M2 to M10

- Length of Fasteners - Up to 126mm

- Types of Fasteners - All Types of heads and threads including multi-level parts by virtue of "machining/ secondary operations".

- Hardness - Case Hardened/Carburized screws to international standards and high tensile machine screws and bolts from ISO 8.8 to 12.9 property class.

QUALITY CONTROL AND ASSURANCE

Quality control and assurance has been the HALLMARK of Adamjee Engineering (Pvt) Ltd right from its inception. Our leadership in the local market - along with the repeat export business for more than twenty years now - endorses this aspect. It is an essential part of the manufacturing process of our products and is strictly monitored throughout the production process.

At the raw material stage, we perform incoming inspection of all our consignments on a random basis in order to ensure that the chemical & mechanical properties of Wire Rod / Wire are within acceptable levels.

At the machining level "part cards" are used to check the dimensions of the products. Further down the production line, hardness values, case depths & plating thicknesses are also checked in accordance with Quality Control Plans. Final Inspections are carried out to monitor the appearance, the sharpness of points & threads keeping in mind the end-use & application of the products.The International Standards that we follow are British, JIS and DIN standards

Another key aspect of maintaining the quality of our products, as we have to come to realize and understand, is that of "traceability". Giving due importance to this aspect of our business, we have over the years introduced procedures to ensure traceability at every stage of the production chain.

PRODUCT RANGE

STANDARD FASTENERS

Catering to the demand of a wide range of retailers and end-users throughout the country, the company has over the years expanded its range of products to Woodscrews, Self-Tapping Screws, Drywall Screws, Self-Drilling Screws, Machine Screws (both BSW and Metric sizes), Roofing Bolts, High Tensile Hex Bolts, High Tensile Socket Head Cap Screws, Solid Rivets and Aluminium Blind Rivets. The above mentioned product categories are then further divided into sub-categories based on their "head types" such Countersunk Head, Pan Head, Cheese Head, Raised Cheese Head, Round Head, Mushroom Head, Button Head, Flanged Head, Bugle Head, Washer Head and so on. All in all, Adamjee Engineering (Pvt) Limited manufactures over 1,000 sizes, most of which are available in our finished goods store at all times.

SPECIAL FASTENERS

Staying abreast with the challenges of the fasteners field, we have recently introduced special fasteners that involve various machining operations - in additional to conventional cold forging and thread rolling - such as turning, grooving, chamfering, drilling and grinding. These products have been inducted to primarily cater to the automotive industry which has been undergoing an unprecedented growth in Pakistan. In keeping with the unwavering vision of the management of the company, Adamjee Engineering (Pvt) limited is now focusing on "value added" fasteners where, due the nature of the application, the attributes of the products are complex with zero compromise on the quality. Moving forward, the company plans to strengthen its position in the manufacturing of special fasteners by working very closely with the OEM"s, understanding their applications, taking on challenges and developing solutions that successfully meet their requirements in a cost effective manner. This aspect of our organization, we feel, is our "core strength".

INDUSTRIES SERVED

With a wide product range, Adamjee Engineering Pvt Ltd " Fasteners Division is serving almost all the industries in Pakistan including, but not limited to, the following industries:

- Automotive & Auto Parts Manufacturing

- General Industrial Purpose

- Construction

- Furniture Manufacturing

- Home Appliance Manufacturing and many others.