POWDER METAL DIVISION

WHY POWDER METAL TECHNOLOGY?

With today's technology, powder metal parts offer a cost effective alternative over a wider range of applications including parts requiring higher strengths. Since modern production technology can now achieve powder metal parts with high densities, powder metal or sintered steel parts are now being used in an increasing number of unique applications. For cost effective production of your multi-level complex parts, consider these advantages of sintered / powder metal products:

- Reduced cost per part

- High volume production

- Reduction or elimination of secondary machining operations (net shape process)

- Engineered materials that match your specific requirements

ABOUT THE POWDER METAL DIVISION AT ADAMJEE ENGINEERING

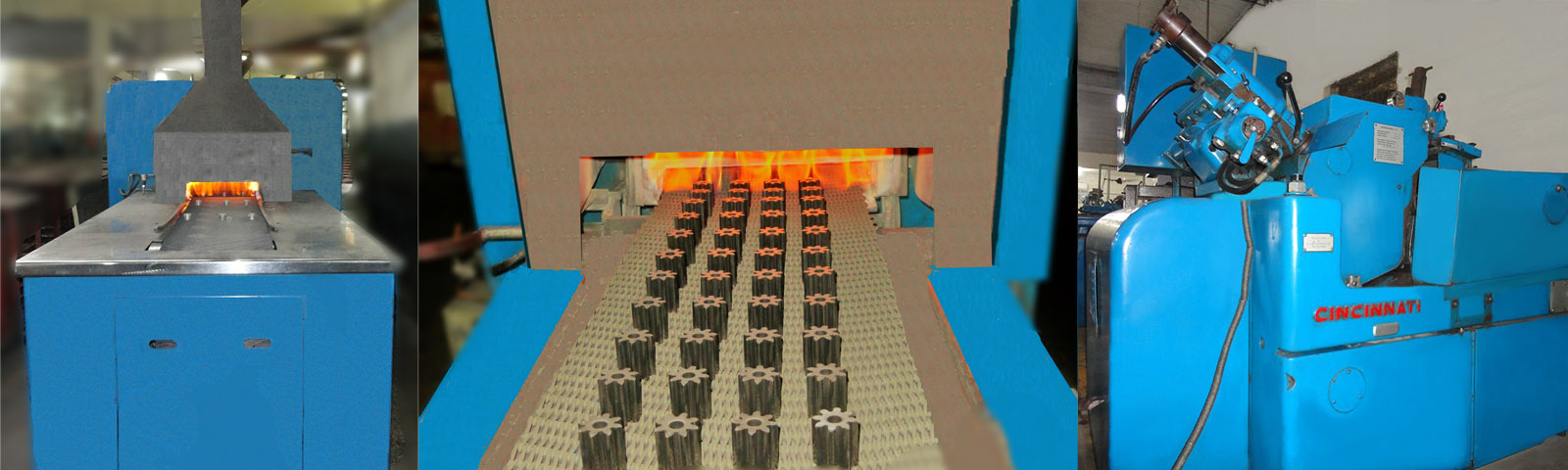

Serving the requirements of industry since 1990, P/M Division at Adamjee Engineering Pvt Ltd has become a premier supplier of sintered powdered metal parts in Pakistan, while also exporting its products worldwide. We research, design, and manufacture close tolerance powder metal parts with exceptional metallurgical characteristics. Our business ideology is to make and reinforce strong associations with our customers by providing highly engineered products and customized client services.

As powder metallurgy specialists, our processes and operations are flexible and cost effective. We can produce parts with complex geometries that would be hard to machine. We use the finest quality of raw materials with specifications tailored to the specific requirement of the customer. While some of our parts are sold in Sintered form, we additionally offer supplementary procedures like CNC & Conventional machining, heat treatment & oil impregnation to enhance the physical and mechanical properties of the product.

With the knowledge of the P/M process, we work with potential and current customers in researching, designing and development of powder metal parts in various applications. We also provide our customers with technical support in recommending suitable materials and needed tolerances. Our technical staff coordinate with our customers to design tooling and fixtures using CAD software.

Our Powder Metal Division is involved in the manufacturing of Sintered Self-lubricating Bushes, Washers, Oil Pump Gears, Oil Pump Gerotors, Shock Absorber parts and other sintered parts for the Automotive, Industrial and Home Appliances industries. Adamjee Engineering (Pvt) Ltd offers more than 800 sintered powder metal parts catering to local as well as the export market (India, China, Germany, UK, India, Poland & Turkey).

Our emphasis is always on continual improvement of our parts and processes. We take pride in being a cost effective, quality focused and on-time supplier for our OEMs and aftermarket customers both locally and globally.

CONTACT US today to learn more about our range of products and capabilities.

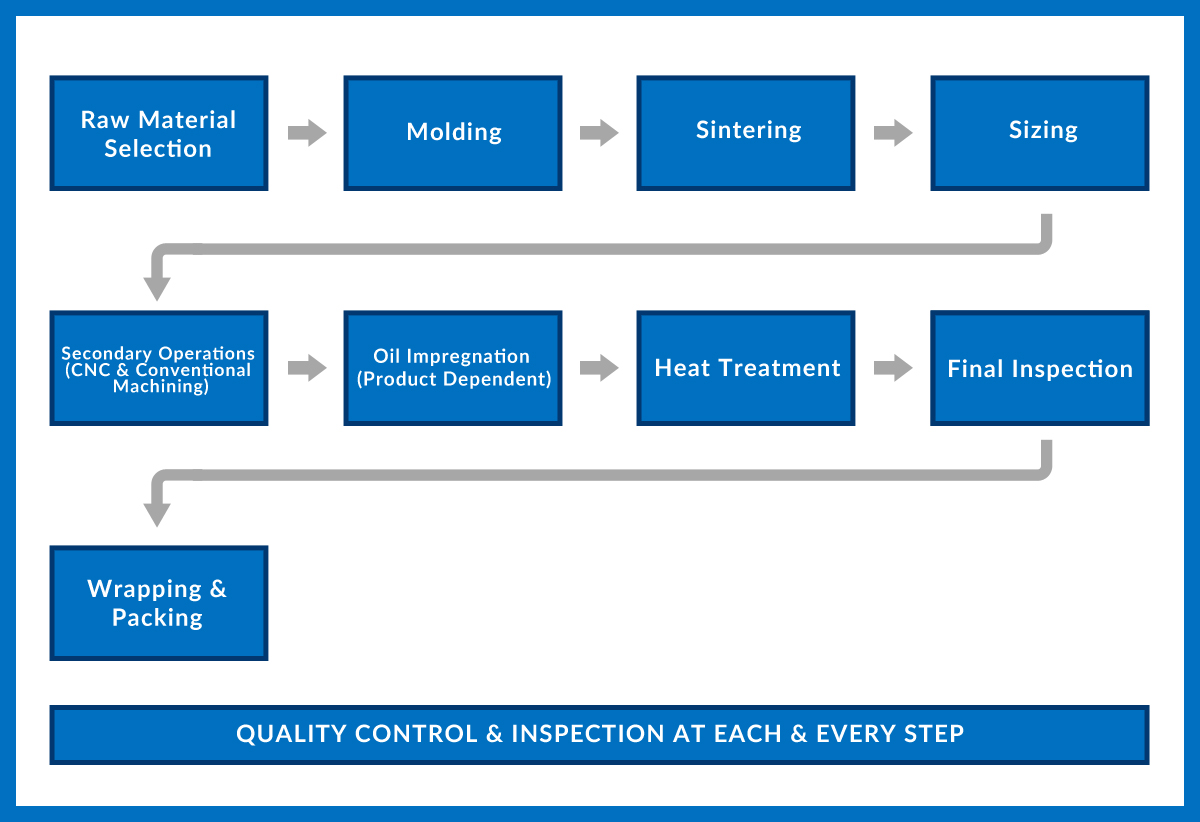

PROCESS FLOW OF SINTERED / POWDER METAL (P/M) PARTS

RAW MATERIAL SELECTION FOR SINTERED / POWDER METAL PARTS

We procure our powder from the best raw material suppliers in Europe, USA & Canada and can provide our customers with the broadest material selection in the industry to meet their wide range of needs. Following are the different powder mixes we are currently using to manufacture sintered parts for our customers.

- 100% Bronze Powder

- Diluted Bronze Powder

- Iron / Steel Powder

- Iron Alloyed / Diffused Steels Powder

- Copper - Iron Premix Powder

Our metal powders are engineered to your needs and tailored to your applications. When selecting the best PM material for a particular application, consideration is given to customer-specific requirements such as strength, ductility, and wear-resistance.

CONTACT US today to learn more about our range of products and capabilities.

PRODUCTION FACILITIES IN P/M DIVISION

Powder Metal Division of Adamjee Engineering (Pvt) Ltd, with its state of the art machinery and equipment offers complete design and engineering services to the customers as well as process and product development. At Adamjee Engineering (Pvt) Ltd, we have a long standing experience working with steel, iron, and other materials.

| S.No | Process | Machines (In-house) |

|---|---|---|

| 1 | Molding / Sizing Operation | Presses ranging from 20 - 100 ton |

| 2 | Sintering Operation | Sintering furnaces with atmosphere controlled sintering (Endogas). |

| 3 | Secondary Operations | CNC & Conventional Machining (Turning, Facing, Tapering, Grooving, Chamfering), Drilling, Tapping, Grinding (Cylindrical & Surface), Heat Treatment, Burnishing, Milling & Slotting, Vibratory Finishing, Barrel Tumbling, Rust Inhibit Dip, Oil Impregnation |

CONTACT US today to learn more about our range of products and capabilities.

PRODUCTION CAPABILITIES

Following are some of the key design parameters for powder metallurgy products produced at our production facility.

- Mass of Product - Max 450 grams

- Height/Length of Product - Max 50 mm

- Outer Diameter - 70 mm.

- Density - Max 7.10 gm/cc (depending upon premix powders)

- Hardness - Max 85 HRB (can go up to 35 HRC with heat treatment process).

CONTACT US today to learn more about our range of products and capabilities.

QUALITY CONTROL & ASSURANCE

Quality Control and Assurance has been the HALLMARK of Adamjee Engineering (Pvt) Ltd right from the beginning. Our leadership in the local market along with sound export volumes endorses this aspect of the company. Quality Control is of key importance in our processes and it is critically monitored throughout the production process.

In order to maintain the same quality level while avoiding batch to batch variations, we follow a Lean Manufacturing System by employing QUALITY CONTROL PLANS for each and every product bearing the details of the processes to be followed during the production along-with the dimensional tolerances and testing specifications. This has helped us reducing waste and eliminated/reduced costly sizing processes.

In addition to all of the above we provide testing & other facilities to our customers. Some of the facilities we offer to our customers are as follows.

- Aid in Design for Manufacturability

- Process Monitoring

- Hardness Testing

- Density Checking

- CAD Facilities

- Tensile, Breaking Force & Radial Crush Strength Testing

CONTACT US today to learn more about our range of products and capabilities.

POWDER METAL / SINTERED PRODUCT RANGE WITH APPLICATIONS

Adamjee Engineering Pvt Ltd - Powder Metal Division, has the capability to produce many parts suitable for powder metal. We provide a wide variety of powdered metal parts including self-lubricating bushes / bearings, small structural components, oil pump gerotors, oil pump gears and many more parts of varying size and complexity.

| S.No | Product Category | Industries Served | Used in / for |

|---|---|---|---|

| 1 | Oil Pump Gerotors | Automotive & Industrial |

For a comprehensive list of products, please download list of oil pump gerotors from Download section. |

| 2 | Oil Pump Gears & Idler Gears | Automotive |

For a comprehensive list of products, please download list of oil pump gears from Download section. |

| 3 | Shock Absorber Parts | Automotive |

|

| 4 | Self-Lubricating Bushes | Automotive, Fan Industry & Home Appliances | We supply an extensive range of sintered bushes in cylindrical, flanged and spherical shapes using iron, iron/copper, diluted bronze & 100 % bronze powders. We are familiar and are able to maintain MPIF, ISO, DIN & ASTM standards for both material & tolerances. For a comprehensive list of products, please download list of bushes from Download section. |

INDUSTRY STANDARDS

- MPIF - Metal Powder Industries Federation

- ASTM - American Society for Testing and Materials

- JIS - Japanese Industrial Standards

- DIN - Deutsches Institut für Normung

- ISO - International Organization for Standardization

CONTACT US today to learn more about our range of products and capabilities.